In the firing phase the brick is transformed into the finished product, terracotta bricks.

The size of the tunnel determine the production capacity of the kiln.

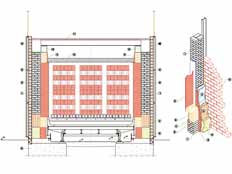

The tunnel kiln is structurally built as a tunnel with floor rails and doors on both ends.

The fire is still in the central area of the tunnel and the bricks placed on the cars go through it, warm up, are fired and cool.

The bricks are therefore those to move within the tunnel, along their path the changes in temperature are adjusted by an ideal firing curve, adapted to the chemical physical type of the product, up to the completion of the cycle.

The kiln construction materials bear resistance and thermal insulation properties to withstand the high temperatures and limit the power consumption.

The tunnel can be supplied with prefabricated walls, or with refractory bricks

Pre-heating zone

First third of the tunnel from the entrance, where heating of the material placed in the kiln occurs and where the chimney extracting the exhaust smokes is positioned.

Fire zone

Central part of the tunnel where the burners are located therefore being the fire zone

Cooling zone

Last third of the tunnel towards the exit, area where the heat is withdrawn to be partly conveyed to the dryer and partly expelled through the chimney.

On the vault or on the outside walls, external piping to the tunnel feed the gas or diesel fuel and air, to the burners, these produce a combustion that generates the heat needed to achieve the baking temperature (max 1050° C).

All the equipment (chimneys, heat exchangers, ventilation, doors, shutters, transfers, burners) is controlled by instruments adjusted by means of a management software that allows the control of the firing following a default curve, set in accordance with the type of clay, the volume of the brick and

the cooling curve. In the tunnel the metal structure cars, equipped with special wheels, travel on the rail line. The cars have a loading surface fitted with a refractory layer, that insulates the metallic structure of the cars from the upper zone where the brick will come into contact with the fire.

When exiting the kiln the products are unloaded from the cars that go back into the cycle, and forwarded to the packaging area.

The supervision system controls through the PLC all the operations and is essential to optimize the drying cycle, consumption and minimize waste.

| TUNNEL KILN - PREFABRICATED GALLERY MODULAR | ||||

|---|---|---|---|---|

| CODE | KILN SECTION mm | PACKS N. | OUTPUT TON/DAY | DIMENSION EXT. mm |

| MODULAR 3 | 4200 X 2100 | 6 | 300 / 400 | 5860 X 3700 |

| MODULAR 4 | 5450 X 2100 | 8 | 400 / 600 | 7110 X 3700 |

| MODULAR 5 | 6730 X 2100 | 10 | 600 / 1000 | 8390 X 3700 |

| MODULAR 6 | 8010 X 2100 | 12 | 1000 / 1500 | 9670 X 3700 |

FORNACE BALLATORE GIUSEPPE

DI BALLATORE MAURO & C. -S.N.C.

Strada Vecchia per Chieri 65

14019 Villanova D’asti AT)

P.IVA 00904730058

Tel. +39 0141 946.680

Fax +39 0141 945.539

Email: info@ballatore.it