BOX FEEDERS

MACHINES DESCRIPTION

The hoppers with extraction belt are especially suited to dose light weight or small sized materials, they are a practical and economical solution to dose light materials.

TECHNICAL DATA

The hoppers with extraction belt are mainly made out of a robust hopper under which is a flat rubber tape is placed.

| HOPPER WITH EXTRACTION BELT NE/G series CODE F-01-23 | |||||

|---|---|---|---|---|---|

| CODE | TYPE | MOUTH DIMENSION HOPPER VOLUME mm m³ | PRODUCTION m³/h | INSTALLED POWER Kw | MACHINE WEIGHT Kg |

| F-01-23-01-000 | NE/G 45/1 | 450×1000 5 | 1 / 15 | 2,2 | 1.500 |

| F-01-23-04-000 | NE/G80/3,5 | 800×3500 6 | 1 / 15 | 1,1+3 | 2.800 |

| F-01-23-06-000 | NE/G 80/6 | 800×6000 10 | 1 / 15 | 3+3 | 3.500 |

| ACCESSORIES FOR HOPPER WITH EXTRACTION BELT CODE F-01-50 | |||||

| CODE | DESCRIPTION | ||||

| All the box feeders are supplied with standard multi-voltage motors | |||||

| F-01-50-01-000 | Mechanical speed variator | ||||

| F-01-50-02-000 | Belt servo-ventilated motors | ||||

| F-01-50-04-000 | MAGHREB type reel shaft | ||||

| F-01-50-05-000 | Anti-sliding device with marine chain | ||||

| F-01-50-06-000 | Box feeder internal wall lining in AISI 304 | ||||

| F-01-50-07-000 | Box feeder internal wall lining in polizene | ||||

| F-01-50-08-000 | Cleaning belt under the machine | ||||

| F-01-50-09-000 | Belt rotation controlling device | ||||

| F-01-50-10-000 | Shaft rotation controlling device | ||||

| F-01-50-11-000 | Machine installation base | ||||

| F-01-50-12-000 | Loading hopper with shovel | ||||

| F-01-50-13-000 | Additional loading hopper upper side with shovel | ||||

| F-01-50-14-000 | Storage hopper (silos) | ||||

| F-01-50-15-000 | Storage hopper external structure | ||||

| F-01-50-16-000 | Hopper internal wall lining in polizene | ||||

| F-01-50-18-000 | Step ladder with gangway | ||||

| F-01-50-19-000 | Hopper covering hood | ||||

| F-01-50-20-000 | Electrical wiring on the machine | ||||

| F-01-50-21-000 | SONAR / RADAR device for filling control | ||||

| F-01-50-22-000 | Frequency variator (INVERTER) in a box on the machine | ||||

| F-01-50-23-000 | Customised varnishing from RAL table (RAL 6011 green as standard) | ||||

| F-01-50-24-000 | Hopper drawing |

Machine functions

Rubber belt box feeders are particularly suited to dose out light or small sized materials. The rubber belt allows to hold the material without dispersion and is cheaper than the metal belt.

Rubber belt box feeders may be used as feeding devices to the rolling mill, the milling shaft works as distributor and spreads the clay on the cylinder width, allowing proper feeding of the mill. They can be equipped with a hopper having variable volume so as to increase the loading capacity.

Machine description

The box feeder is built out of a sturdy metal frame dimensioned according to the production or requested storage volume.

Within the frame, a multi-canvas rubber belt, turns to enable the conveying of the product.

| RUBBER BELT BOX FEEDERS CRG series CODE F-01-20/22 | |||||

|---|---|---|---|---|---|

| CODE | TYPE | USEFUL DIMENSION mm | PRODUCTION m³/hr | INSTALLED POWER Kw | MACHINE WEIGHT Kg |

| F-01-20-02-000 | CRG 80/4 | 800 X 3500 | 2 / 20 | 1,5 + 3 | 2.300 |

| F-01-20-03-000 | CRG 80/5 | 800 X 4500 | 2 / 20 | 1,5 + 3 | 2.600 |

| F-01-21-02-000 | CRG 100/4 | 1000 X 3500 | 3 / 25 | 1,5 + 4 | 2.900 |

| F-01-21-03-000 | CRG 100/5 | 1000 X 4500 | 3 / 25 | 2,2 + 4 | 3.400 |

| F-01-21-04-000 | CRG 100/6 | 1000 X 5500 | 3 / 25 | 3 + 4 | 3.900 |

| F-01-22-02-000 | CRG 120/4 | 1200 X 3500 | 4 / 30 | 3 + 5,5 | 4.900 |

| F-01-22-03-000 | CRG 120/5 | 1200 X 4500 | 4 / 30 | 4 + 5,5 | 5.400 |

| F-01-22-04-000 | CRG 120/6 | 1200 X 5500 | 4 / 30 | 4 + 5,5 | 5.900 |

Machine functions

Receiving the clay extracted from the quarry, dosing, feeding the processing lines that come after.

– Main box: it is used as feeder, accumulator and for the deposit of material.

– Storage: it is a storage of pre-processed clay.

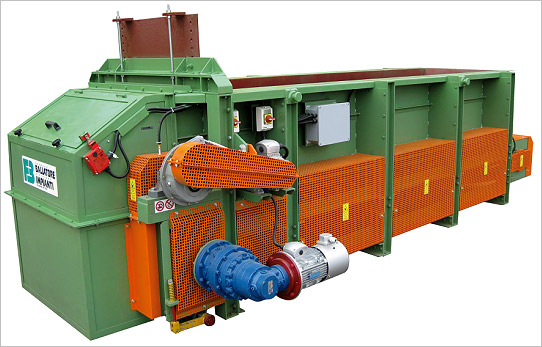

Machine description

The box feeder is built out of a sturdy metal frame dimensioned according to the production or requested storage volume.

Within the frame, a modular robust metal chain, turns to enable the conveying of the product usually on a conveyor belt, or directly inside the machine. In the construction of the machine, the utmost importance was given to sturdiness to guarantee a continuous and safe operation in time.

| METAL BELT BOX FEEDERS CFD series – CODE F-01-01/07 | |||||

|---|---|---|---|---|---|

| CODE | TYPE | USEFUL DIMENSION mm | PRODUCTION m³/hr | INSTALLED POWER Kw | MACHINE WEIGHT Kg |

| F-01-01-01-000 | CFD 75/3 | 750 X 2500 | 3 / 25 | 1,5 + 3 | 1.600 |

| F-01-01-02-000 | CFD75/4 | 750 X 3500 | 3 / 25 | 1,5 + 3 | 2.000 |

| F-01-01-03-000 | CFD75/5 | 750 X 4500 | 3 / 25 | 2,2 + 3 | 2.400 |

| F-01-03-02-000 | CFD100/4 | 1000 X 3500 | 5 / 30 | 2,2 + 4 | 3.800 |

| F-01-03-03-000 | CFD100/5 | 1000 X 4500 | 5 / 30 | 3 + 4 | 4.500 |

| F-01-03-04-000 | CFD100/6 | 1000 X 5500 | 5 / 30 | 3 + 4 | 5.200 |

| F-01-05-04-000 | CFD120/6 | 1200 X 5500 | 10 / 50 | 4 + 5,5 | 7.100 |

| F-01-05-06-000 | CFD120/8 | 1200 X 7500 | 10 / 50 | 5,5 + 5,5 | 8.700 |

| F-01-07-04-000 | CFD150/6 | 1500 X 5500 | 20 / 80 | 5,5 + 7,5 | 8.500 |

| F-01-07-06-000 | CFD150/8 | 1500 X 7500 | 20 / 80 | 5,5 + 7,5 | 10.500 |

| F-01-07-08-000 | CFD150/10 | 1500 X 9500 | 20 / 80 | 7,5 + 7,5 | 12.500 |

| METAL BELT BOX FEEDERS CFD/P heavy series – CODE F-01-08/09 | |||||

| CODE | TYPE | USEFUL DIMENSION mm | PRODUCTION m³/hr | INSTALLED POWER Kw | MACHINE WEIGHT Kg |

| F-01-08-04-000 | CFD/P 150/6 | 1500 X 5500 | 20 / 80 | 5,5 + 7,5 | 9.600 |

| F-01-08-06-000 | CFD/P 150/8 | 1500 X 7500 | 20 / 80 | 5,5 + 7,5 | 11.800 |

| F-01-08-08-000 | CFD/P 150/10 | 1500 X 9500 | 20 / 80 | 7,5 + 7,5 | 14.000 |

| F-01-09-08-000 | CFD/P 180/10 | 1800 X 9500 | 20 / 120 | 11 + 11 | 16.800 |

| F-01-09-10-000 | CFD/P 180/12 | 1800 X 11500 | 20 / 120 | 11 + 11 | 19.500 |

| METAL BELT HOPPER BOX FEEDERS CFD/ECO series – CODE F-01-12 | |||||

| CODE | TYPE | MOUTH DIMENSION HOPPER VOLUME mm m³ | PRODUCTION m³/hr | INSTALLED POWER Kw | MACHINE WEIGHT Kg |

| F-01-12-04-000 | CFD/ECO 120/6 | 1200 X 5500 10 | 5 / 25 | 3 + 4 | 4.500 |

| F-01-12-06-000 | CFD/ECO 120/8 | 1200 X 750 13 | 5 / 25 | 4 + 4 | 6.000 |

| METAL BELT EXTRACTORS NE/M series – CODE F-01-15 | |||||

| CODE | TYPE | MOUTH DIMENSION HOPPER VOLUME mm m³ | PRODUCTION m³/hr | INSTALLED POWER Kw | MACHINE WEIGHT Kg |

| F-01-15-02-000 | NE/M 75/4 | 750 x 3500 6 | 2 / 10 | 1,5 + 3 | 3.200 |

| F-01-15-04-000 | NE/M 75/6 | 750 x 550 10 | 2 / 10 | 3 + 4 | 4.000 |

FORNACE BALLATORE GIUSEPPE

DI BALLATORE MAURO & C. -S.N.C.

Strada Vecchia per Chieri 65

14019 Villanova D’asti AT)

P.IVA 00904730058

Tel. +39 0141 946.680

Fax +39 0141 945.539

Email: info@ballatore.it