CRUSHER

Machine functions

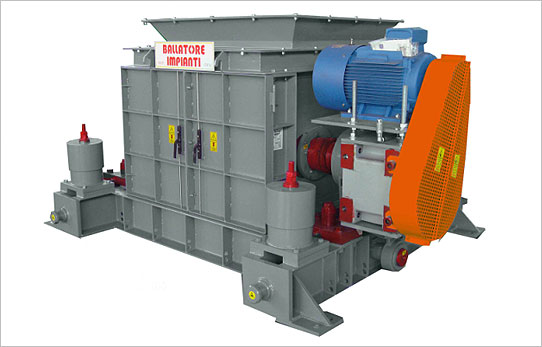

The machine is suitable to crush and chop both “green” bricks from the rejects of the extruder production, and the “dry” bricks coming from the waste of the dryer, so as to allow their reutilisation, sending once again the crushed waste product in the furnace production cycle.

Machine description

The dry and green material crusher is made out of a robust metal structure, equipped with two counter-rotating shafts, provided with knives lined with wear-resistant material. The knives which crush the waste material, undergo wear and are therefore interchangeable.

| CRUSHERS FRA/S-FRA/V series CODE F-02-05 | |||||

|---|---|---|---|---|---|

| CODE | TYPE | DIMENSIONS mm VAT | PRODUCTION m³/hr | INSTALLED POWER Kw | MACHINE WEIGHT Kg |

| F-02-05-01-000 | FRA/S 100 | 1000 x 740 | variable | 2,2 + 2,2 | 1.000 |

| F-02-05-02-000 | FRA/S 150 | 1500 x 740 | variable | 3 + 3 | 1350 |

| F-02-06-01-000 | FRA/V 80 | 810 x 280 | variable | 7,5 | 400 |

| F-02-06-02-000 | FRA/V 100 | 800 x 1200 | variable | 11 | 600 |

| CRUSHER ACCESSORIES CODE F-02-50 | |||||

| CODE | DESCRIPTION | ||||

| F-02-50-01-000 | Rotation controlling device on fast shaft | ||||

| F-02-50-02-000 | Rotation controlling device on slow shaft | ||||

| F-02-50-03-000 | Damping unit | ||||

| F-02-50-04-000 | Wear-resistant facing | ||||

| F-02-50-07-000 | Machine installation basement | ||||

| F-02-50-08-000 | Balcony with railing and ladder | ||||

| F-02-50-09-000 | Dust recovery hood | ||||

| F-02-50-10-000 | Dust suppressor | ||||

| F-02-50-12-000 | Electrical wiring on the machine | ||||

| F-02-50-13-000 | Customised varnishing from RAL table (RAL 6011 green as standard) |

Machine functions

The sizer is used to reduce the dimension of large blocks of clay coming from the quarry, avoiding them to roll on the conveyor belts. The sizer is fitted before the crusher.

Machine description

The sizer is made out of two shafts having very robust knives located at a set distance in relation to the type of clay. These knives have a converging rotation with differentiated speed.

The machine replaces the shaft normally applied to box feeders thus guaranteeing constant feeding of the installations.

| CALIBRATORI serie CL COD.F-02-SIZER CL series CODE F-02-01 01 | |||||

|---|---|---|---|---|---|

| CODE | TYPE | VAT DIMENSION mm | PRODUCTION m³/hrr | INSTALLED POWER Kw | MACHINE WEIGHT Kg |

| F-02-01-03-000 | CL 100 | 1200 X 1200 | 15 / 30 | 7,5 + 7,5 | 1.500 |

| F-02-01-06-000 | CL 130 | 1400 X 1200 | 30 / 60 | 9,2 + 9,2 | 2.150 |

| F-02-01-01-000 | CL 170 | 1700 X 1200 | 30 / 100 | 11 + 11 | 2.800 |

| BREAKING MILL ACCESSORIES CODE F-02-50 | |||||

| CODE | DESCRIPTION | ||||

| F-02-50-01-000 | Rotation controlling device on fast shaft | ||||

| F-02-50-02-000 | Rotation controlling device on slow shaft | ||||

| F-02-50-03-000 | Damping unit | ||||

| F-02-50-04-000 | Wear-resistant facing | ||||

| F-02-50-05-000 | Grinder for cylinders | ||||

| F-02-50-06-000 | Kit with motor, belts, installation slides, drive protection device | ||||

| F-02-50-07-000 | Machine installation basement | ||||

| F-02-50-08-000 | Balcony with railing and ladder | ||||

| F-02-50-09-000 | Dust recovery hood | ||||

| F-02-50-10-000 | Dust suppressor | ||||

| F-02-50-11-000 | Automatic bearing lubrication system | ||||

| F-02-50-12-000 | Electrical wiring on the machine | ||||

| F-02-50-13-000 | SONAR / RADAR device for filling control | ||||

| F-02-50-13-000 | Customised varnishing from RAL table (RAL 6011 green as standard) |

Machine functions

The bar crusher breaks up the clods previously reduced by the clod mill to further reduce them.

For it to function in the best way, it is necessary to feed the machine over the whole width of the cylinders, and this can be achieved with a suitably wide belt provided with a clay levelling device.

The machine is particularly indicated for the treatment of very dry clays, as it offers a higher quality disintegration.

Machine description

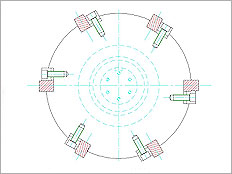

The bar crusher is made out of a sturdy steel structure, on which two shafts are installed to sustain two counter-rotating cylinders placed one opposite the other, a smooth one with a greater diameter and a toothed one with a smaller diameter, placed very close together.

The smooth cylinder revolves at a very low speed, the fast cylinder revolves at a speed seven times faster so as for the clay to be squashed on the other cylinder surface by the knives present on the other cylinder. The speed is adjusted through two independent motors.

Hydraulic safety systems halt the machine in the event of overload.

The bar crusher is equipped with a safety system installed on the fast shaft that allows the enlargement of the cylinder gauge to have very hard stones or clods to go through.

This device is useful to safeguard the integrity of the machine from accidental overloads and to adjust the distance between the cylinders.

When the safety device comes on, the machine will produce a sound through a specific device, thus allowing the operators to intervene.

The rollers, also called sleeve or shell, are:

the smooth one in high quality nodular cast iron (slow cylinder),

the toothed one in quality steel with interchangeable blades, because subjected to wear (fast cylinder).

The smooth roller is equipped with a pneumatic scraper, easily interchangeable so as to maintain the surface clean.

The size of the machine is set depending on the required hourly production quantity and on the type of clay.

| BAR CRUSHERS DF series CODE F-02-03 | |||||

|---|---|---|---|---|---|

| CODE | TYPE | CYLINDER DIMENSION mm | PRODUCTION m³/hrr | INSTALLED POWER Kw | MACHINE WEIGHT Kg |

| F-02-03-02-000 | DF 80 | 400 X 800 800 X 800 | 20 / 40 | 45 + 11 | 6.000 |

| F-02-03-03-000 | DF 100 | 400 X 1000 800 X 1000 | 30 / 70 | 55 + 18,5 | 8.000 |

| F-02-03-04-000 | DF 120 | 400 X 1200 800 X 1200 | 60 / 100 | 75 + 22 | 10.000 |

Machine functions

It may receive clods coming from the quarry, with dimensions up to 300 mm. and take them to a size ranging from 0 to 50 mm. This machine is essential in the clay preparation department.

Machine description

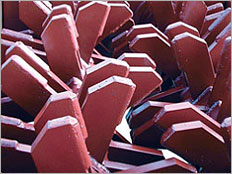

The disk mill is made out of a sturdy metal structure, equipped with two counter-rotating shafts, equipped with finger plates with wear-resistant edging.

The finger plates which break the clods, undergo wear and are therefore interchangeable.

The RM version of the machine has a slow tilting shaft to adjust the gauge balancing between the disks and therefore adjustable depending on the usage requirements.

The RM crusher is equipped with a particular spring system which allows the enlargement of the shafts to have very hard stones or clods to go through. This device is useful to safeguard the integrity of the machine from accidental overloads. When the safeguard device is turned on, the machine will produce a sound thus allowing the operators to intervene.

| CLOD BREAKING MILL FR series CODE F-02-02 | |||||

|---|---|---|---|---|---|

| CODE | TYPE | CYLINDER DIMENSION mm | PRODUCTION m³/hrr | INSTALLED POWER Kw | MACHINE WEIGHT Kg |

| F-02-02-01-000 | FR 10 | 350 x 600 | 3 / 10 | 3 + 2,2 | 850 |

| F-02-02-03-000 | FR 30 | 350 x 900 | 10 / 20 | 15 + 11 | 4.500 |

| F-02-02-05-000 | FR 50 rm | 600 x 1000 | 20 / 50 | 30 + 22 | 8.500 |

| F-02-02-07-000 | FR 75 rm | 600 x 1250 | 50 / 75 | 37 + 22 | 9.500 |

| F-02-02-10-000 | FR 100 rm | 600 x 1500 | 75 / 100 | 45 + 37 | 11.500 |

| F-02-02-15-000 | FR 150 | 600 x 2000 | 100 / 150 | 75 + 55 | 14.400 |

| BREAKING MILL ACCESSORIES CODE F-02-50 | |||||

| CODE | DESCRIPTION | ||||

| F-02-50-01-000 | Rotation controlling device on fast shaft | ||||

| F-02-50-02-000 | Rotation controlling device on slow shaft | ||||

| F-02-50-03-000 | Damping unit | ||||

| F-02-50-04-000 | Wear-resistant facing | ||||

| F-02-50-05-000 | Grinder for cylinders | ||||

| F-02-50-06-000 | Kit with motor, belts, installation slides, drive protection device | ||||

| F-02-50-07-000 | Machine installation basement | ||||

| F-02-50-08-000 | Balcony with railing and ladder | ||||

| F-02-50-09-000 | Dust recovery hood | ||||

| F-02-50-10-000 | Dust suppressor | ||||

| F-02-50-11-000 | Automatic bearing lubrication system | ||||

| F-02-50-12-000 | Electrical wiring on the machine | ||||

| F-02-50-13-000 | SONAR / RADAR device for filling control | ||||

| F-02-50-13-000 | Customised varnishing from RAL table (RAL 6011 green as standard)) |

FORNACE BALLATORE GIUSEPPE

DI BALLATORE MAURO & C. -S.N.C.

Strada Vecchia per Chieri 65

14019 Villanova D’asti AT)

P.IVA 00904730058

Tel. +39 0141 946.680

Fax +39 0141 945.539

Email: info@ballatore.it