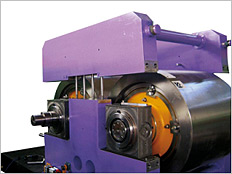

STONE REMOVING ROLLER MILL

Machine functions

The stone removing roller mill eliminate stones and other residues present in the clay and it is used in the pre-processing department. For it to function in the best way, it is necessary to feed the machine over the whole width of the cylinders, and this can be achieved with a suitably wide belt provided with a clay levelling device. In order to safeguard the integrity of the machine, deironing devices should be installed on the feeding belts so as to eliminate any metal residues sometimes present in the clay (nails, pieces of metal). For a constant rolling it is essential to maintain the smooth cylinder perfectly parallel with the fluted roller.

Machine description

The removing roller mill of the SP series stone is made out of two sturdy steel shoulders, on which two shafts are installed to sustain two counter-rotating cylinders placed only a few millimetres apart, one opposite the other and adjustable through adjustment screws. The two cylinders revolve at different speeds, one has a smooth surface, the other has a removal slot, so for any stone to slide towards a lateral discharge hatch to be eliminated. The smooth roller is equipped with an easily interchangeable pneumatic scraper, so as to maintain the surface clean. The size of the machine is set depending on the required hourly production quantity and on the type of clay.

| STONE REMOVING ROLLER MILL SP series CODE F-03-01 | |||||

|---|---|---|---|---|---|

| CODE | TYPE | CYLINDER DIMENSION mm | PRODUCTION m³/hr | INSTALLED POWER Kw | MACHINE WEIGHT Kg |

| F-03-01-02-000 | SP 75/100 | 750 X 1000 | 40 / 70 | 55 + 37 | 7.000 |

| F-03-01-03-000 | SP 75/100 | 750 X 1000 | 50 / 100 | 75 + 45 | 9.500 |

| ACCESSORIES FOR STONE REMOVING ROLLER MILLS CODE F-03-50 | |||||

| CODE | DESCRIPTION | ||||

| F-03-50-01-000 | Rotation controlling device on fast shaft | ||||

| F-03-50-02-000 | Rotation controlling device on slow shaft | ||||

| F-03-50-03-000 | Hydraulic control safety device | ||||

| F-03-50-04-000 | Wear-resistant facing on grooved cylinder for SP series | ||||

| F-03-50-05-000 | Grinder for smooth cylinder | ||||

| F-02-50-06-000 | Kit with motor, belts, installation slides, drive protection device | ||||

| F-03-50-07-000 | Machine installation basement | ||||

| F-03-50-08-000 | Balcony with railing and ladder | ||||

| F-03-50-09-000 | Dust recovery hood | ||||

| F-02-50-10-000 | Dust suppressor | ||||

| F-03-50-11-000 | Automatic bearing lubrication system | ||||

| F-03-50-12-000 | Electrical wiring on the machine | ||||

| F-03-50-15-000 | Customised varnishing from RAL table (RAL 6011 green as standard) |

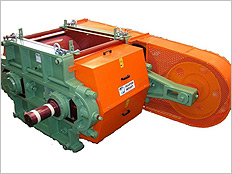

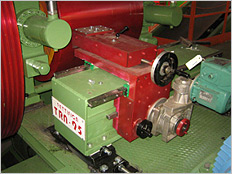

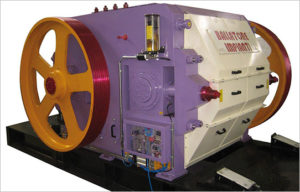

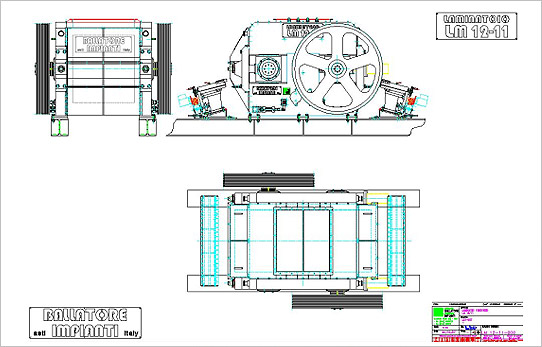

COGGING ROLLER MILL, REFINING ROLLER MILL

Machine functions

Il laminatoio lamina l’argilla in particelle di pochi millimetri.

Il laminatoio sgrossatore si utilizza nel reparto di prelavorazione dell’argilla.

Il laminatoio raffinatore si utilizza nel reparto di produzione dell’argilla.

I due tipi di funzione variano in base allo scartamento dei cilindri, che determinano la dimensione della laminazione. Per una funzione ottimale è necessario una alimentazione della macchina distribuita su tutta la larghezza dei cilindri, ottenibile con un nastro di larghezza adeguata e dotato di livellatore di argilla.

Per salvaguardare l’integrità dei cilindri è opportuno installare sui nastri che la alimentano dei deferizzatori, che elimineranno eventuali residui ferrosi, talvolta presenti nell’argilla (chiodi, pezzi di ferro ecc…).

Per una laminazione costante, è indispensabile mantenere i cilindri perfettamente paralleli e rettificati. Il passaggio dell’argilla provoca l’usura dei mantelli, i quali devono essere periodicamente spianati (rettificati), per mezzo di rettifiche Machine functions

The mill rolls the clay in very fine particles.

The cogging mill is used in the clay pre-processing department.

The refining mill is used in the clay production department.

The two types of function vary according to the cylinder gauge, which determine the rolling size.

For it to function in the best way, it is necessary to feed the machine over the whole width of the cylinders, and this can be achieved with a suitably wide belt provided with a clay levelling device .

In order to safeguard the integrity of the machine, deironing devices should be installed on the feeding belts so as to eliminate any metal residues sometimes present in the clay (nails, pieces of metal).

For a constant rolling it is essential to maintain the cylinder smooth and perfectly parallel. The passage of clay wears the cylinder shell which has to be periodically ground, through grinders placed on both cylinders.

Machine description

The roller mill is made out of two sturdy steel shoulders, on which two shafts are installed to sustain two counter-rotating cylinders placed only a few millimetres apart, one opposite the other and adjustable through adjustment screws.

The two cylinders revolve at different speeds, so as for one to squash the clay on the other cylinder surface, the speed is adjusted through two independent motors. Hydraulic safety systems halt the machine in the event of overload.

The high quality nodular cast iron rollers, also called sleeve or shell, are interchangeable because subjected to wear.

The rollers are equipped with pneumatically driven scrapers, easily interchangeable in order for their surface to be kept clean.

The size of the machine is set depending on the required hourly production quantity and on the type of clay.

| ROLLER MILL LM series CODE F-03 | |||||

|---|---|---|---|---|---|

| CODE | TYPE | CYLINDER DIMENSION mm | PRODUCTION m³/hr 1mm 3 mm | INSTALLED POWER Kw | MACHINE WEIGHT Kg |

| F-03-02-02-000 | LM 30/50 | 300 x 500 | 2 10 | 9,2 + 7,5 | 1.000 |

| F-03-02-03-000 | LM 75/60 | 750 x 600 | 10 30 | 37 + 22 | 5200 |

| F-03-02-04-000 | LM 80/80 | 800 x 800 | 15 40 | 55 + 45 | 7500 |

| F-03-02-08-000 | LM 100/80 | 1000 x 800 | 18 50 | 75 + 45 | 10500 |

| F-03-02-10-000 | LM 120/90 | 1200 x 900 | 25 75 | 90 + 55 | 16000 |

| F-03-02-11-000 | LM 120/110 | 1200 x 1100 | 30 90 | 90 + 75 | 23000 |

| F03-02-14-000 | LM 140/90 | 1400 x 900 | 35 105 | 160 + 90 | 28000 |

| F03-02-15-000 | LM 140/120 | 1400 x 1200 | 35 105 | 160 + 132 | 32000 |

| ROLLER MILL ACCESSORIES | |||||

| CODE | DESCRIPTION | ||||

| F-03-50-01-000 | Rotation controlling device on fast shaft | ||||

| F-03-50-02-000 | Rotation controlling device on slow shaft | ||||

| F-03-50-03-000 | Hydraulic control safety device | ||||

| F-03-50-04-000 | Wear-resistant facing on grooved cylinder for SP series | ||||

| F-03-50-05-000 | Grinder for cylinders | ||||

| F-02-50-06-000 | Kit with motor, belts, installation slides, drive protection device | ||||

| F-03-50-07-000 | Machine installation basement | ||||

| F-03-50-08-000 | Balcony with railing and ladder | ||||

| F-03-50-09-000 | Dust recovery hood | ||||

| F-02-50-10-000 | Dust suppressor | ||||

| F-03-50-11-000 | Automatic bearing lubrication system | ||||

| F-03-50-12-000 | Electrical wiring on the machine | ||||

| F-03-50-13-000 | SONAR / RADAR device for filling control | ||||

| F-02-50-14-000 | Spare shells HV 530 or HV 580 hardness (VICKERS scale) | ||||

| F-02-50-15-000 | Spare shells HB 530/580 or HB 580/630 hardness (BRINELL scale) | ||||

| F-03-50-16-000 | Customised varnishing from RAL table (RAL 6011 green as standard) |

FORNACE BALLATORE GIUSEPPE

DI BALLATORE MAURO & C. -S.N.C.

Strada Vecchia per Chieri 65

14019 Villanova D’asti AT)

P.IVA 00904730058

Tel. +39 0141 946.680

Fax +39 0141 945.539

Email: info@ballatore.it